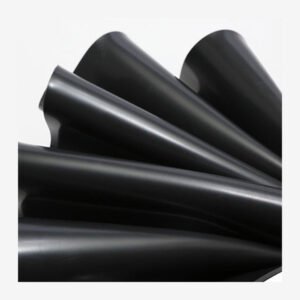

It is produced by hydrogenating the unsaturated double bonds contained in the main chain of NBR, also known as highly saturated NBR. Since HNBR has a reasonable molecular structure, it not only inherits the properties of NBR such as oil resistance and abrasion resistance, but also has more excellent heat resistance, oxidation resistance, ozone resistance, and chemical resistance, which can be comparable to fluorine rubber, and it can replace fluorine rubber, CR, NBR, and other special rubbers in many aspects.

JIURUN supports the best always. For rubber and plastic products, we are the better choice for you.

© 2022 AccountingKit Elementor Template. All Rights Reserved.

WhatsApp us

If you need to inquire or need samples, leave your contact information, and we will contact you immediately!

Sample is free, just need pay the express fee, or you have a delivery account.

We will contact you within 1 working day, please pay attention to the email with the suffix “JIURUN”.