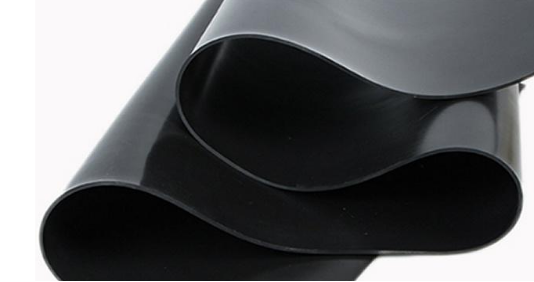

Do you know HNBR? Is it the same as NBR? What is the difference between the two? This article will be from the production process, material properties, and application scenarios for you to explain the differences between the two, to help you choose the required materials more precisely

Difference in the production process:

NBR is a rubber synthesized from butadiene and acrylonitrile by low-temperature emulsion polymerization, while HNBR is a highly saturated elastomer obtained by special hydrogenation of nitrile rubber.

Difference in characteristics:

NBR performs better in oil resistance, abrasion resistance, heat resistance, and adhesion. However, the low-temperature resistance and elasticity of NBR will be weakened with the increase of nitrile content, the ozone resistance of NBR is also poor, it is not suitable for direct exposure to the outdoors, and the insulating property is weak.

Compared with NBR, HNBR not only retains the good properties of NBR such as oil resistance and abrasion resistance, but also has further improvement. The structure of hydrogenated HNBR is highly saturated, giving it better heat resistance and excellent chemical resistance. And it makes up for the shortcomings of NBR’s lack of ozone resistance, with good ozone and heat aging resistance. In addition, HNBR also has the advantages of high strength, tear-resistance, and other advantages, the overall performance is excellent.

Differences in application scenarios:

NBR is often made into seals and gaskets for industrial machinery and equipment, such as hydraulic systems, compressors, and other applications that require effective sealing against fuels, oils, and chemicals, due to its good oil resistance and sealing properties; NBR can also be used for conveyor belts in the mining industry, as lining material for storage tanks, and in expansion joints.

HNBR, on the other hand, in addition to the application scenarios of NBR, can also be used in oil and gas extraction due to its improved high-temperature resistance and chemical resistance; HNBR is also used in a variety of seals for nuclear power plants due to its good radiation resistance.

2 回复

How can I buy it?

You can contact us via whatapp:+86 152 97386860