What is silicone?

Organosilicon usually refers to organic compounds, and it is customary to often regard those compounds that connect organic groups with silicon atoms through oxygen, sulfur, nitrogen, etc., as organosilicon compounds.

What are the properties of silicone?

Silicone is a versatile synthetic material known for its unique properties. Some of the key features of silicones include:

- Heat resistance: Silicone has excellent heat resistance and can usually withstand a temperature range of -60°C to 260°C (-76°F to 500°F), depending on the specific formula.

- Flexibility and elasticity: silica gel has high flexibility and excellent elasticity. It can be stretched and compressed without losing its original shape, making it suitable for a variety of applications that require movement or deformation.

- Waterproof: Silica gel is hydrophobic, making it suitable for use as a sealant, gasket, or waterproof paint.

- Chemical resistance: Silicone has good resistance to many chemicals, including acids, bases, solvents, and oils.

- Electrical insulation: Silicone is an excellent electrical insulator that can withstand high voltage and has a low dielectric constant, making it suitable for insulation, cable coating, and electronic components.

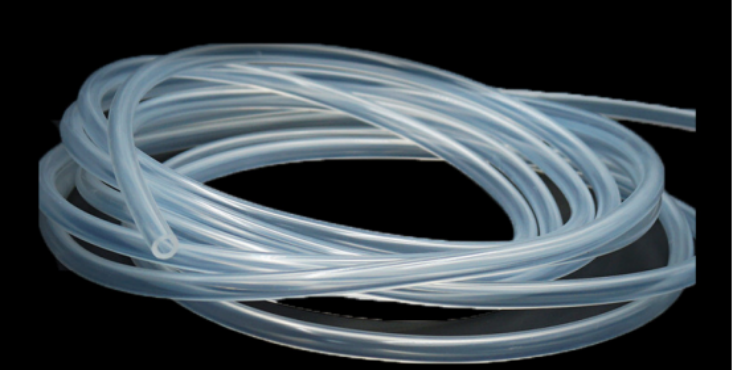

- Biocompatibility: Silicone is biocompatible and suitable for a variety of medical and healthcare applications, such as implants, prosthetics, and medical tubes.

- Transparency and color diversity: Silicone can be transparent or translucent, and has a variety of colors to choose from.

These are just some of the key properties of silicone, there are many more specific properties for different silicone formulations and applications.

What are the silicone products usually?

Common silicone products are ordinary silicone sheets, platinum-solidified silicon wafers, silicone foam sheets, and so on. There are also many special silicone products, for example, high tear resistance silicone sheets, with excellent tear strength, can withstand large tensile force, and are not easy to break, while having excellent durability, good elasticity and resilience, chemical stability, and high-temperature resistance.

What is the process of producing silica gel?

The Silica gel vapor process and precipitation process are two different processes used to produce silica gel.

Silica gel gas phase method:

- Raw materials: silicon tetrachloride, oxygen (or air), and hydrogen.

- The organic silicon compound vapor reacts with the gas to form silica particles under high-temperature conditions.

- During the reaction, these particles are aggregated into larger particles in the aggregator.

- After separation, it is sent to the acid removal furnace, and the silica is washed with nitrogenous air to the PH value of 4 ~ 6

The particle size and pore structure of silica gel can be better controlled by the vapor phase method.

Silica gel precipitation method:

- Add the prepared sodium silicate to the solvent, the common solvent is water or organic solvent.

- By adding a catalyst and regulator to make a hydrolysis reaction, and then precipitate to form silica particles.

- Finally, the obtained silica particles are filtered, washed, and dried to obtain silica gel.

Precipitation typically results in larger particle sizes and wider pore size distributions than vapor phase methods.

Is there any difference between the silica gel vapor phase method and the precipitation method?

The main differences between the two approaches are:

- Appearance: The silica gel produced by the gas phase method is generally better transparent, and can even achieve complete transparency, while the silica gel produced by the precipitation method can only achieve translucent or opaque.

- Performance: The density of silica gel made by vapor process is high, the tensile strength, tearing strength, and elongation at break of silica rubber products under the same hardness is better than that of precipitation silicone rubber products, and the tensile strength of vapor silica gel will not turn white, and its environmental protection index is higher.

- Application: gas phase silica gel due to its characteristics make it suitable for pressure cooker rings, silicone wire, food grade seals, food grade and medical grade silicone tubes with special requirements

Precipitation silica gel products are mostly used in industrial hoses, rubber strips, conventional seals, seals, and parts with high tensile strength and elongation requirements (such as tear resistance).

2 回复

It’s too detailed!

Thanks!